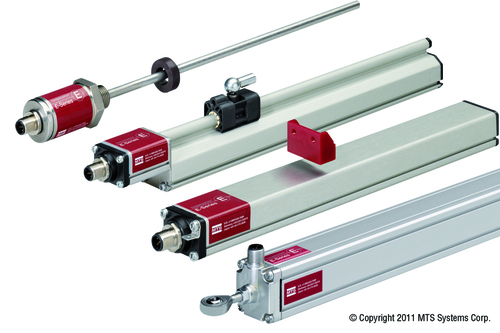

Temposonic LVDT

86700 INR/Piece

Product Details:

- Sensor Type Magnetostrictive Linear Position Sensor

- Humidity % Up to 90% RH, non-condensing

- Temperature Range -40C to +85C

- Equipment Type Temposonic LVDT (Linear Variable Differential Transformer)

- Connectivity Type Analog 420 mA, Voltage, or Digital interface

- Measurement Range Up to 7600 mm

- Resolution As low as 1 micron

- Click to View more

X

Temposonic LVDT Price And Quantity

- 1 Piece

- 86700 INR/Piece

Temposonic LVDT Product Specifications

- 24 volt

- As low as 1 micron

- 420 mA

- Up to 7600 mm

- Not Applicable (Analog Output)

- Up to 90% RH, non-condensing

- Magnetostrictive Linear Position Sensor

- Up to 0.05% F.S. (depends on model)

- Analog 420 mA, Voltage, or Digital interface

- Customizable, standard from 25 mm to 7600 mm

- Temposonic LVDT (Linear Variable Differential Transformer)

- Stainless Steel Housing

- -40C to +85C

Temposonic LVDT Trade Information

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- 1000 Piece Per Month

- 1 Week

Product Description

Conversion Principles:- Electromagnetic

- Magnetoelectric

- Electrostatic

- Analog and discrete output

- Digital

- Static and dynamic qualities

- Sensitivity or transfer ratio - E=y / x or y is the change in output quantity y when input quantity x is changed by x

- Output signalrange of operating frequency

- Static error of conversion or of the signal

Types of LVDTs

LD400:Miniature DC Output Displacement Transducers with Acetal BearingsLVDT Sensors - determine whether you need to measure a relative current: C-in, AC-out, DC-in, DC-out; or measuring resonant frequencies of coils as a function of coil position, frequency based devices.

LD400:Miniature DC Output Displacement Transducers with Acetal BearingsLVDT Sensors - determine whether you need to measure a relative current: C-in, AC-out, DC-in, DC-out; or measuring resonant frequencies of coils as a function of coil position, frequency based devices.

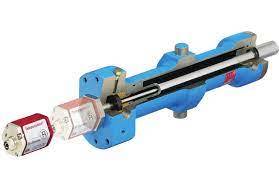

Reliable Position Sensing for Industrial Automation

Engineered for precise linear position measurement, Temposonic LVDTs excel in automated systems, hydraulic cylinders, and handling equipment. Their repeatability as low as 1 micron and high accuracy (up to 0.05% F.S.) increase efficiency and process control. Stainless steel construction and international protection ratings assure operational reliability in tough environments.

Flexible Integration and Customization

Designed with customizable stroke lengths (standard: 25 mm 7600 mm), various output signals (analog or digital), and multiple mounting options, the Temposonic LVDT seamlessly integrates into new or existing setups. With options for different cable lengths and connectivity types, users can tailor the sensor to meet specific performance and installation requirements.

FAQs of Temposonic LVDT:

Q: How do I install a Temposonic LVDT in my industrial system?

A: Installation can be accomplished using either brackets or flange mounting. Ensure that the sensor is securely attached to the measurement area, with the appropriate cable length and connectivity type selected for your control system. Always follow manufacturer guidelines for optimal performance.Q: What environments are suitable for Temposonic LVDT operation?

A: These sensors are suitable for demanding environments with temperatures from -40C to +85C, humidity up to 90% RH (non-condensing), and exposure to vibrations (up to 15 g) and shocks (up to 100 g), thanks to IP67/IP68 protection and stainless steel construction.Q: What are the benefits of using a Temposonic LVDT for measurement?

A: Temposonic LVDTs offer highly accurate (up to 0.05% F.S.), repeatable (0.01 mm) linear measurements, customizable ranges, and robust durability. Their long mechanical life and resistance to harsh conditions result in reduced maintenance and improved process reliability.Q: When should I choose a digital output versus an analog output?

A: Select a digital output (such as SSI, Profibus, CANbus, or EtherCAT) when your system requires advanced data communication or integration with modern automation controllers. Choose analog (420 mA, voltage) for simpler applications or legacy system compatibility.Q: Where can Temposonic LVDTs be used in industrial applications?

A: They are ideal for use in automation systems, hydraulic cylinders, material handling equipment, and any application needing precise linear position feedback in industrial settings.Q: What is the process for customizing stroke lengths or cable lengths?

A: You can request custom stroke or cable lengths when placing an order. Specify your requirements to the supplier; standard stroke ranges are from 25 mm to 7600 mm and standard cable length is 2 m, with other lengths available upon request.Q: How does the high vibration and shock resistance enhance sensor reliability?

A: With resistance to 15 g vibration and 100 g shock, Temposonic LVDTs maintain accuracy and operational integrity even in dynamic or impact-prone industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email